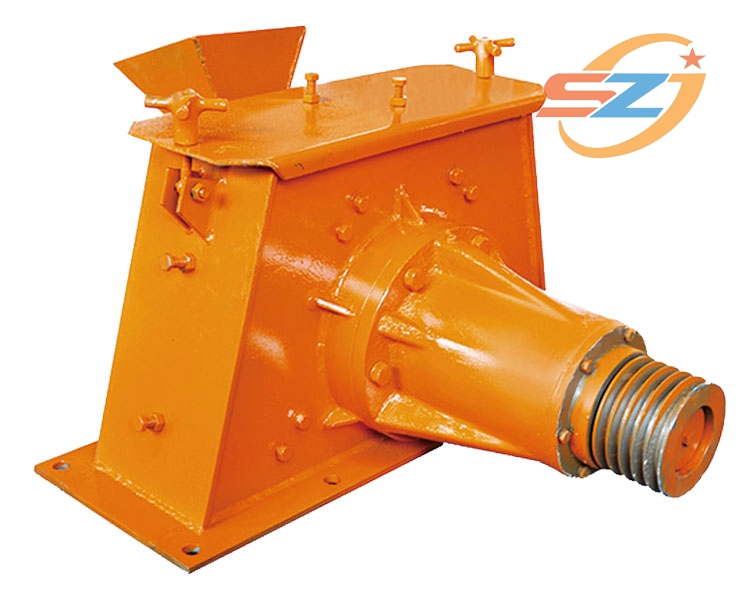

BHQ03 Shot Blasting Machine

Product Introduction

BHQ03 series belt type new shot blasting machine is sanzhuji in absorbing foreign advanced shot blasting machine on the basis of independent independent research and development, its characteristics are.

1 blasting impeller body speed up to 3000r/min, throwing speed up to 80m / s, can significantly improve the blasting cleaning effect.

2 The internal sealing of the blast machine is more rigid, reliable and low noise.

3 Compared with the traditional blast machine, its top and side guard poles are made of special structure, with a partial thickness of 70mm, which greatly improves the overall wear resistance.

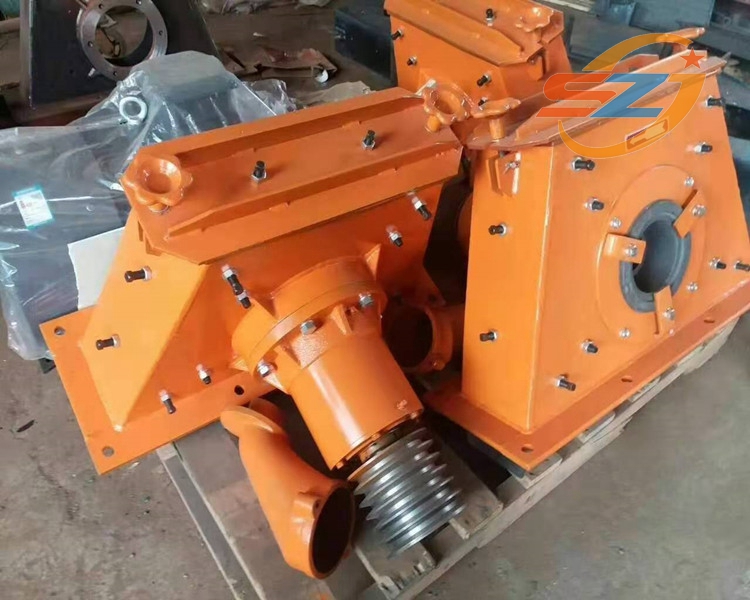

impeller, blade, split shot wheel fastened in the spindle and with its high-speed rotation, directional sleeve fixed in the shell, impeller speed can generally reach 2200 rpm, in and blasting machine for synchronous rotation of the split shot wheel in the acceleration to ensure that the projectile almost no vibration to the blade transmission, blade life ≥ 600 hours; directional sleeve, split shot wheel: ≥ 1500 hours; guard plate: ≥ 3000 hours.

Blade loading and unloading convenient and rapid: blade clamping positioning part dovetail groove and projectile does not contact, blade speed is relatively high, generally up to 78 m / s, blade by dynamic balance detection and blade weighing detection into groups, so as to ensure that the blast machine in the work process to reduce vibration, the product after carburizing quenching, heat treatment surface hardness of ≥ HRC60. impeller using 40Cr forging material production, has a very good dynamic and static Balance and wear resistance; service life (continuous work) more than 6000 hours. The blast machine in the blade, the wheel, the directional sleeve, etc., heat treatment surface hardness of HRC60-65, using special high-chromium wear-resistant cast iron material (Cr20S) production, so that the blade weight difference is controlled within 5 grams, greatly reducing the noise of the blast machine operation, extending the life of wear parts.

The assembly surface of the directional sleeve and the splitting wheel are refined after annealing process to ensure the accuracy of the assembly. Directional sleeve in the process of use, should often check the wear of the rectangular window, when the window wear about 5 mm, shall turn back about 5 mm (according to the direction of rotation of the impeller), when the window wear loss of more than 15 mm should be replaced, otherwise the radial scattering angle of the projectile will increase proportionally, so as to accelerate the wear of the guard and reduce the cleaning efficiency.

The hole of the fixed shaft and directional sleeve on the housing is processed at one time: this can make the gap between the directional sleeve and the shot wheel uniform, greatly improving the efficiency of shot blasting. To ensure that the noise of the machine is less than 85dB, the blast machine is installed with rubber shock absorbing device, the noise of the blasting equipment can be greatly reduced.